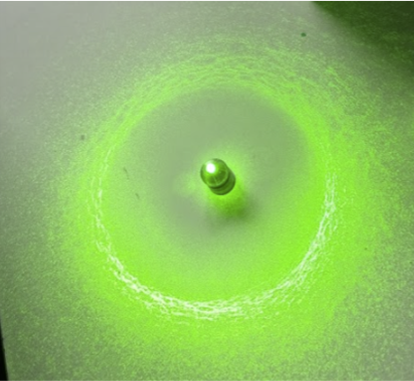

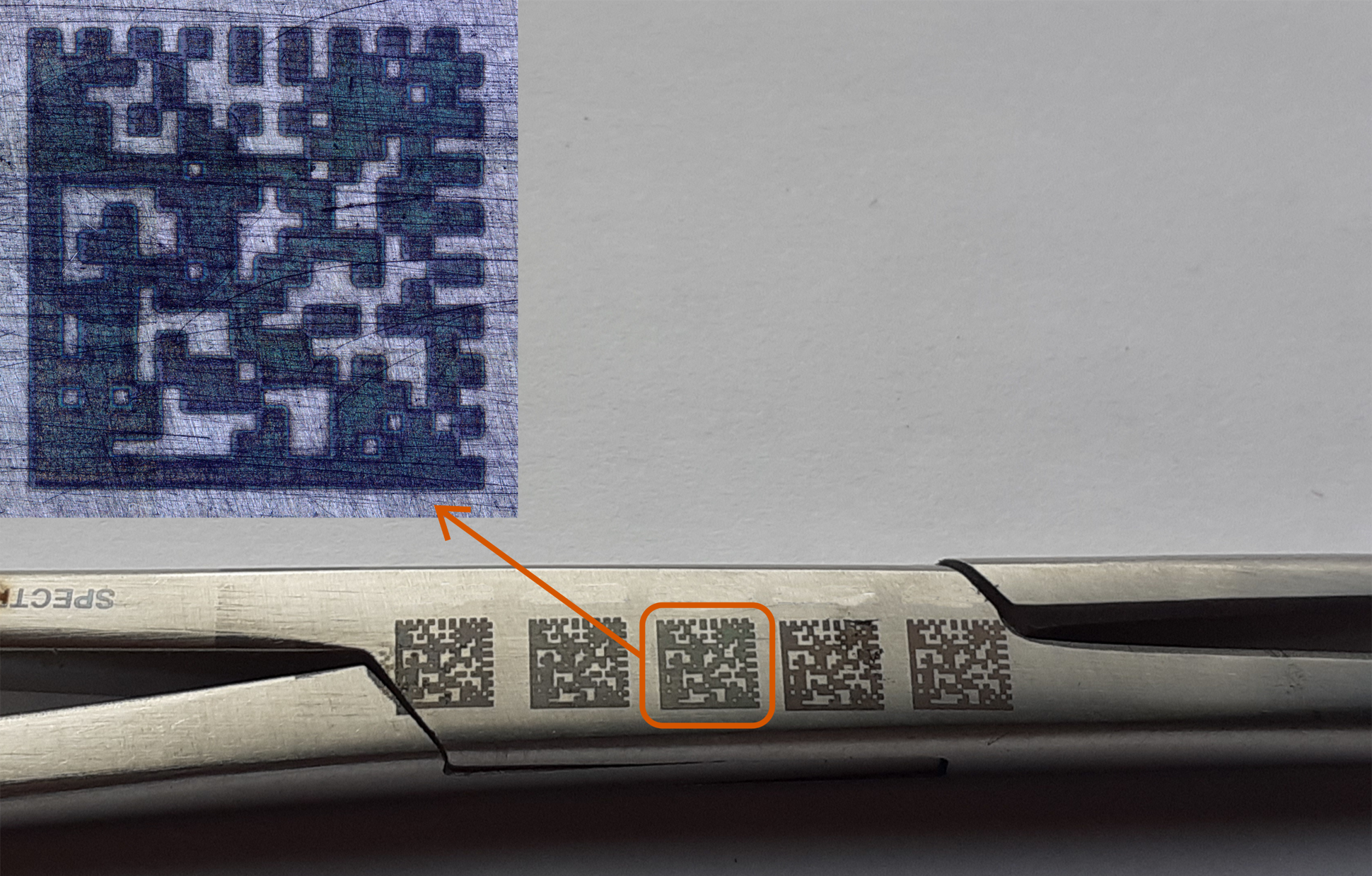

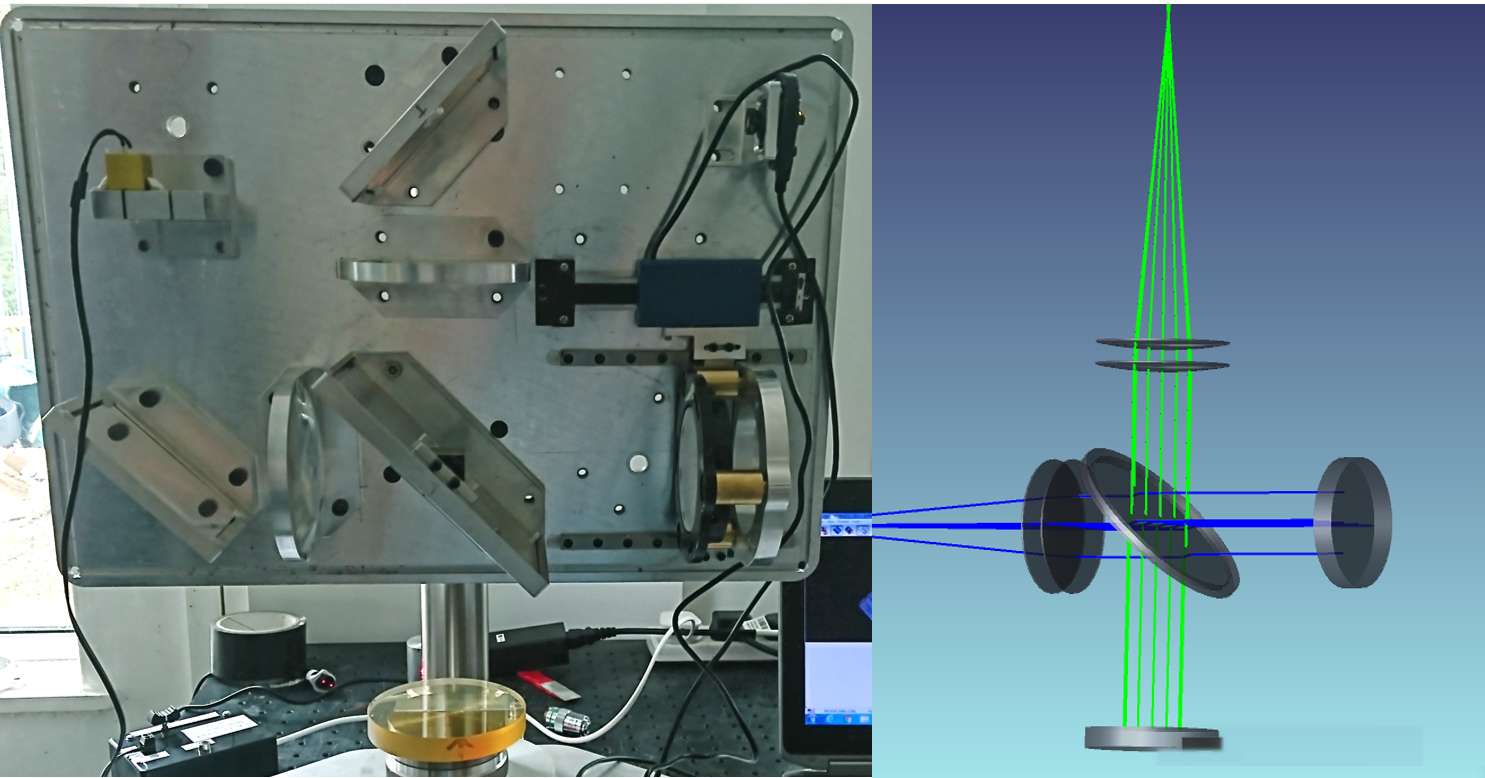

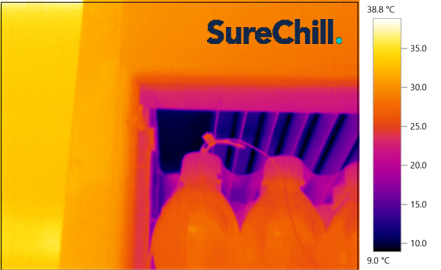

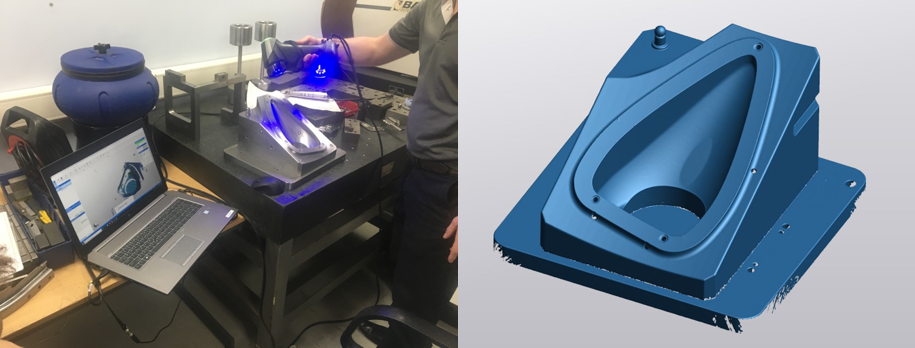

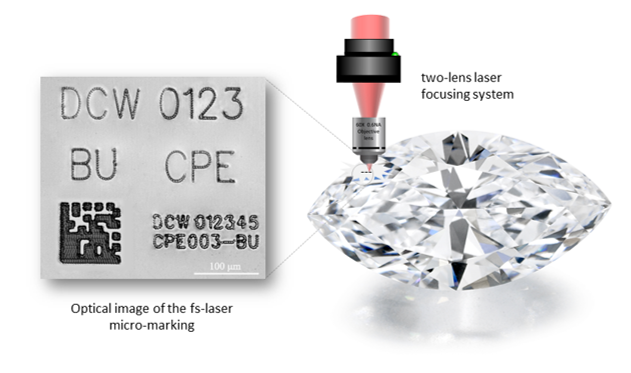

AVoptics have developed a personal boundary marker which uses a laser to highlight a two-meter radius around the wearer. It achieves this by using a laser reflected off a surface in a small device worn by the user. A vital part of this device is a bespoke, highly reflective component. AVoptics have used their capabilities in 3D printing to manufacture a nonreflective prototype component, and in collaboration with the CPE, were able to achieve a highly reflective coating on the surface.

Initially, AVoptics and CPE investigated the feasibility of coating the component using the CPE’s Thin Film Vacuum Coating Research Facility. The investigation concluded that the current material used for 3D printing was unsuitable for the vacuum coating processes, however, a different material suitable for vacuum deposition was identified. Further development work on this is under consideration.

The CPE and AVoptics investigated using reflective automotive spray paint to achieve a metallic reflective surface. With the right combination of sample polishing, surface preparation and spray on paint method, a specular reflection with a high reflectivity was achieved.

Using this novel component, AVoptics was able to develop a working prototype for their laser boundary marker. The Welsh Government was impressed with their working prototype and have invited them to apply for further funding for this project and another Covid related product.