The CPE team were able to offer us a level of specialist expertise that we simply would not have access to “in‐house”. Results were offered through review meetings and further work was progressively staged after these reviews. This process streamlined the Project very effectively and has provided an engineering solution that may have taken several iterative steps had we not had this additional expertise to hand. The CPE team were enthusiastic and were able to communicate with us at exactly the right level to extract the information they needed to assist us. We are very pleased with the project outcome.

Case Studies

The work done by the Bangor CPE team has allowed us to redefine our goals and we believe will produce the solution we seek to create a ground-breaking technology in the field of UVC light disinfection which can be used in the presence of humans without damaging them.

Doing this CPE collaboration was fantastic. I would never have looked at this as a modality for my business until I did this project and with CPE’s expertise it really opened up my eyes to the world of colour and light. I am really excited to take this to the next phase and to see where this could go as I believe this will be one of the most sought-after modalities in the future.

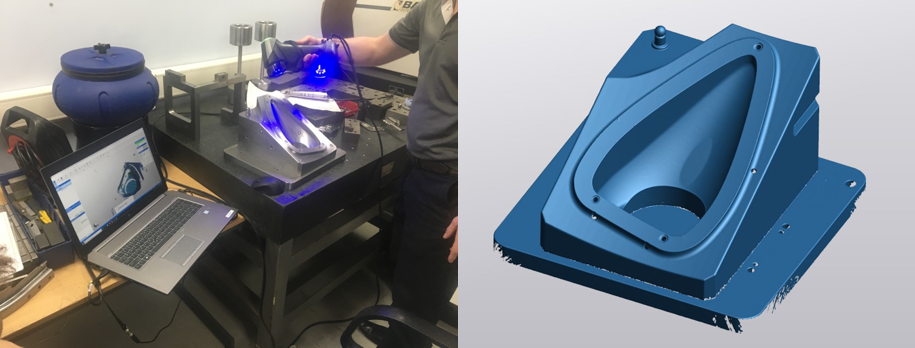

CPE team were very proactive in setting up the joint project and managing it. They provided strong communication throughout the 2-month project, and ran it smoothly to its conclusion. We now have a much stronger understanding of what was possible for our optical product concept and have already identified the follow-up opportunity to take advantage of the CPE’s vacuum coating facility.

We at Mon Naturals were really impressed with CPE and their project capabilities. After initially agreeing to a possible collaboration with the CPE Team, a project was put in place and up and running in no time. This process was efficient and allowed the focus to be on the project rather than the paperwork. From the start this has been a positive experience and I can only thank the team for their professionalism.

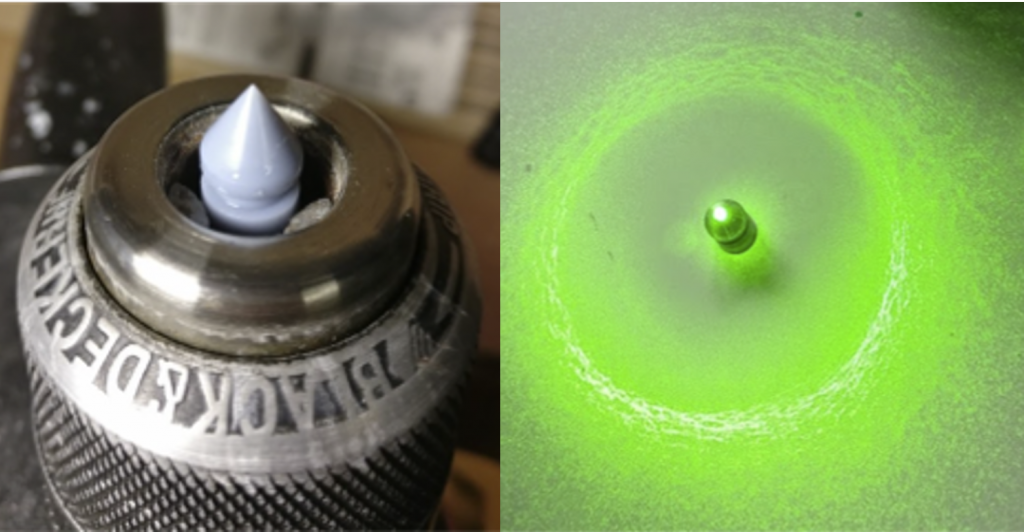

Being a small start up in the Environmental Sector can be daunting when looking for advice and help to progress basic ideas. Producing a collaboration with CPE was not only quick to instigate but provided a sounding board and technical capability to advance our basic idea to prototype stage for further funding. The administration tasks were made simple and without this form of academic help the project may have been on hold indefinitely until spare time and cash flow would allow.

Working with the CPE team has assisted Grafmarine in re-evaluating its manufacturing processes using photonics technology, resulting in the delivery of improved product development, closer supply chain collaboration with SME suppliers in Wales and the realisation that innovation is a core strategy to our growth.

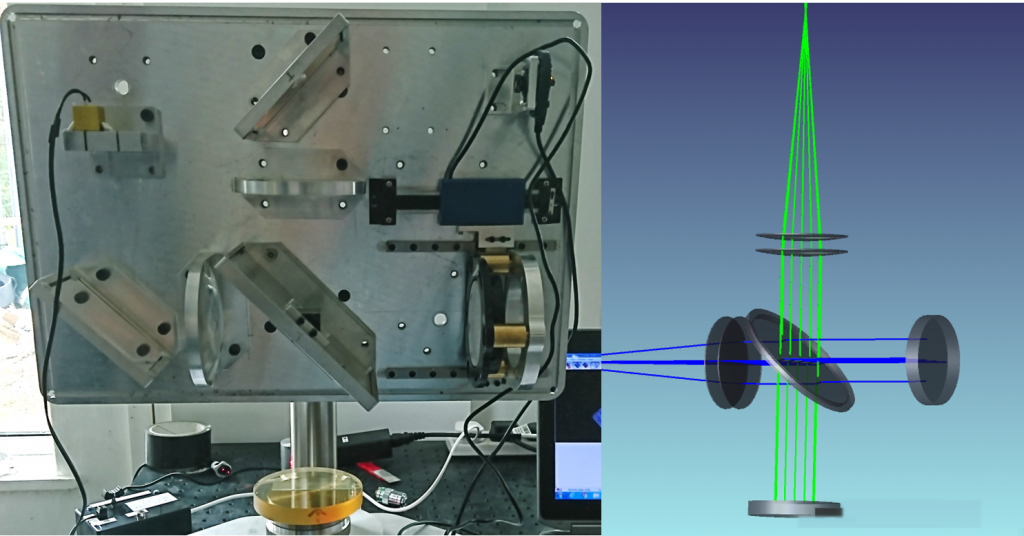

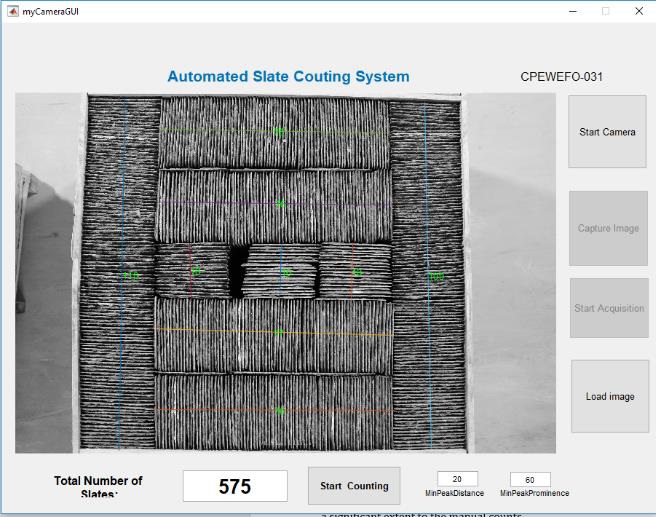

Bangor University CPE team have invested significant time and resources into solving this problem by successfully implementing photonics and bespoke programming. Welsh Slate are looking forward to advancing the project further with Bangor University, with the aims of improving accuracy and implementing pattern recognition, ensuring the system will be able to run successfully in the production environment.

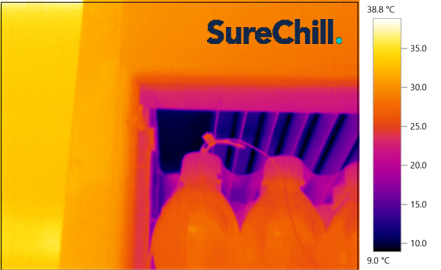

The feasibility study undertaken through CPE has enabled us to ensure with confidence the equipment and budget for the PV enabled power supply for our process developments to progress with our first stage pilot trials in Namibia. Subject to the success of these pilot trials we would be keen to work with the team again on identifying PV requirements as we scale up.

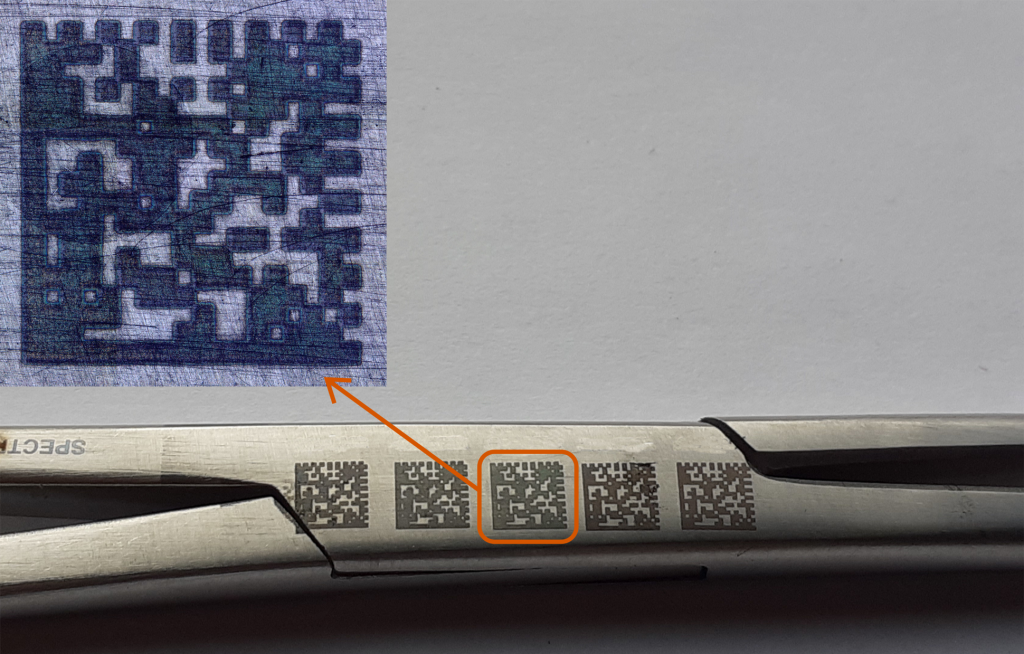

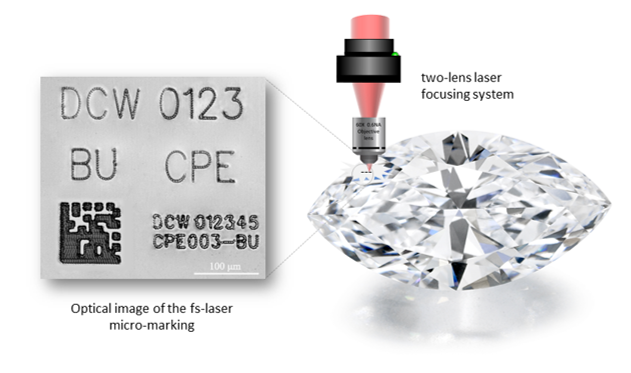

We strongly believe that nano marking using laser scribing, with photonics to uniquely mark the diamonds in a non-destructive way, is the answer for secure tracing and identification. Working with CPE partner Bangor University has clearly showed this is possible in their feasibility study, and we would look forward to working with them again to fully explore this innovative process